Aerospace Digital Transformation

Digital Transformation

Defining Possible in Digital Technology.

Digital Transformation

Defining Possible in Digital Technology.

Why Digital Transformation Matters

Northrop Grumman is harnessing integrated digital technologies to rapidly conceptualize, design, build, and sustain value-driven solutions.

Aerospace Digital Transformation

The defense industry is undergoing a digital transformation. Northrop Grumman is leading the way in partnering with our customers on their digital transformation. We are designing, testing and deploying capabilities faster to respond to current and emerging needs. We have existing partnerships with the U.S. Air Force, U.S. Space Force, U.S. Navy, U.S. Army, other branches of the Department of Defense and NASA to deliver integrated digital capabilities across our portfolio of new and legacy programs.

Our success as a partner in digital transformation includes our expertise in digital engineering, DevSecOps, artificial intelligence/machine learning, advanced manufacturing, and open architecture woven with Lean-Agile methodologies.

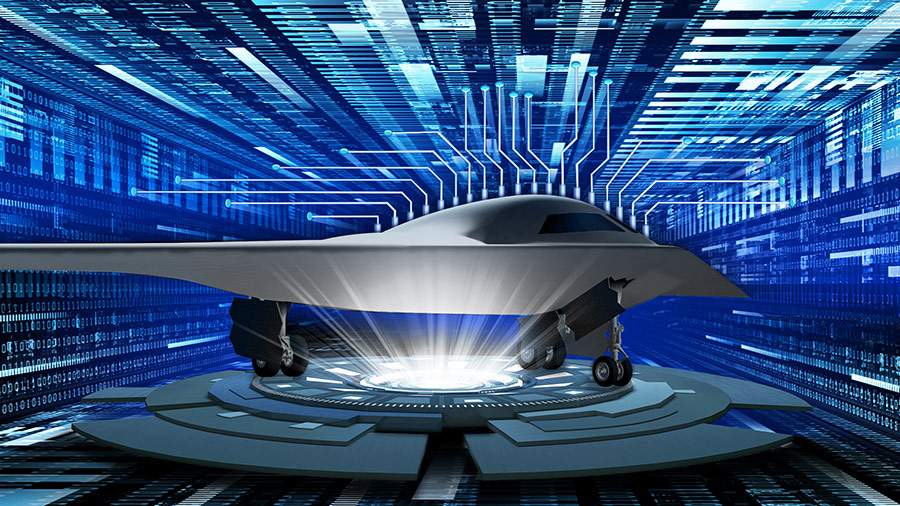

B-21 and Digital Design

In just over two years since completing Critical Design Review, Northrop Grumman has brought its digital design of the B-21 Raider to life, with two test aircraft in production today.

Benefits of Digital Transformation

The results of our digital transformation speak for themselves. Northrop Grumman is architecting the LGM-35A Sentinel (GBSD) program digital engineering ecosystem to be a unified collaboration environment with common tools and processes, thereby enabling effective engineering and manufacturing development.

Digital transformation trends in aerospace and defense industry

Our customers are looking for faster cycle times and more affordable systems to counter rapidly evolving threats with a need to maintain capability and capacity. Northrop Grumman understands the speed of relevance for the warfighter and we are performing at that speed with efficiency and agility. We are at the forefront of implementing digital engineering, DevSecOps and Agile principles and practices across our portfolio of new and legacy programs to meet that need.

How does digital transformation accelerate operations?

By having integrated digital models of our capabilities and platforms it enables a seamless approach. We can make changes in real time and visually see those improvements reflected in the models. What once was a cycle of designing, building, prototyping, and testing a capability or platform can now be done digitally and simultaneously, accelerating operations.

Northrop Grumman’s advanced system integration and validation of our digital models allows us to reduce the need for final platform integration, decreasing time to field and improving affordability.

Digital Engineering

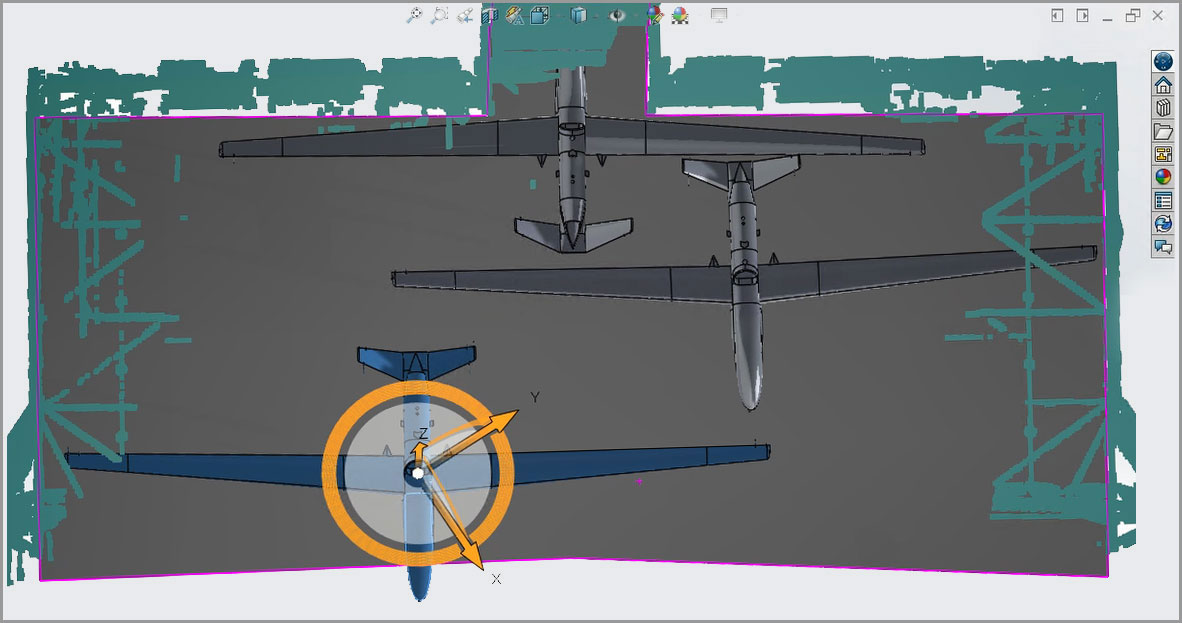

Northrop Grumman continues to optimize the way we work through digital modeling, model-based systems engineering, data analytics, and simulation, while enhancing communication and collaboration across functions and throughout the system life cycle.

With our integrated technological capabilities, we can design, integrate, test and address any issues digitally long before they can arise in the operations and sustainment environments. This contributes to future program affordability and quality. Using our proven open architecture experience, we are able to integrate complex models from diverse sources.

Model-Based Systems Engineering in Aerospace

MB(x) Advancing Model-Based Systems Engineering in Aerospace

At Northrop Grumman, our approach takes Model-Based Systems Engineering further with MB(x) or Model-Based Everything – a mindset of seeking ways to optimize the way we work through modeling and simulation applications, enhancing communication and collaboration across functions and throughout the system life cycle.

Applying modeling and simulation across all functions enables us to innovate and deliver more effectively, from system conception through system retirement increasing the speed of execution.

Digital Twin

By using virtual simulation and real-time data, a digital twin rapidly evaluates system performance in ever-changing environments.

As a founding member of the Object Management Group’s Digital Twin Consortium, Northrop Grumman is committed to partnering with both the commercial and aerospace and defense industry to drive the innovative technology of digital twins forward.

In partnership, this digital twin definition was created.

What is a Digital Twin?

A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity.

- Digital twin systems transform business by accelerating holistic understanding, optimal decision-making, and effective action.

- Digital twins use real-time and historical data to represent the past and present and simulate predicted futures.

- Digital twins are motivated by outcomes, tailored to use cases, powered by integration, built on data, guided by domain knowledge, and implemented in information technology/operational technology systems.

The foundational elements of the definition are captured in the first sentence: the virtual representation, the real-world entities and processes it represents, and the mechanism by which the virtual and real-world entities are synchronized.

By using virtual simulation and real-time data a digital twin rapidly evaluates system performance in ever-changing environments.

What is a Digital Thread?

A digital thread is an extensible, configurable, multi-directional integration of authoritative technical data, software, and information throughout a system’s life cycle, enabling the capture of decision making information and knowledge. With our customers and end user in mind, the digital thread provides the framework for continuous feedback and incremental opportunities to build, refine and verify in a Lean-Agile framework.

DevSecOps

Our mission critical systems require more than just DevSecOps. Which is why, in partnership with the U.S. Air Force, we created an all-encompassing strategy called Dev*Ops (pronounced DevStarOps) to deliver capabilities to our platforms faster and more reliably.

Dev*Ops – the evolution of DevSecOps

Dev*Ops is a set of continuous practices that bridge the gap between development (Dev), operations (Ops), and all other organizations in between (*) responsible for delivering the system. In addition to security (Sec), embedded systems demand a variety of features such as safety or air worthiness. The traditional wildcard character, (*), encompasses all of these specialty demands in the term Dev*Ops – essentially emphasizing speed, quality, focus and security.

Dev*Ops can be applied to all systems and can dramatically change the way we do business.

Dev*Ops achieves these goals by driving changes that deliver benefits such as faster time to delivery, improved quality and cost to the customer, and improved organizational efficiencies that increase productivity.

DevSecOps or Dev*Ops Best Practices

Dev*Ops is more than a process and tools. Dev*Ops drives change through continuous delivery of value, improved quality of systems, and increased affordability.

- Culture – Create a set of values that promote collaboration across functional areas to achieve one common goal.

- People – Empower individuals to come together as collaborative, cross-functional, self-organizing teams.

- Tools – Employ tools to promote transparency, collaboration and automation.

- Process – Utilize lean practices to assure sustainable delivery of value and continuous improvement.

- Technology – Automate every phase to ensure quality and rapid delivery of value.

Artificial Intelligence

Northrop Grumman’s innovative team brings significant corporate experience and investment across our portfolio to create and deliver artificial intelligence and machine learning systems across land, sea, air, space and cyberspace. Our technology is focused on enabling decisions at the speed of the mission in complex and dynamic environments, training in the cloud and driving decision making to the edge in low size, weight and power environments.

Northrop Grumman’s Artificial Intelligence engineers, cognitive scientists and aerospace experts are relentless in seeking new ways to employ this powerful technology.

How is Artificial Intelligence Used in Aerospace?

The result of using machine learning and artificial intelligence across our development process is increased reliability, testing environments that uncover new insights with greater speed and the ability to improve outcomes over time.

In the field, artificial intelligence is critical for giving warfighters the ability to make informed decisions with the speed of relevance. Our proven algorithm development and implementation has developed leading-edge artificial intelligence and machine learning solutions that can process massive amounts of data securely and quickly, delivering actionable intelligence directly into the hands of those who need it most, wherever they are.

As one of the Department of Defense’s most trusted partners, Northrop Grumman is pushing the boundaries of what’s possible to bring forward new and emerging capabilities needed to succeed in the age of data-driven warfare.

Autonomy in Digital Transformation

The trends are clear: autonomy is a critical technology that will lead our customers into the future. As technology moves beyond automation, autonomy and autonomous systems bring efficiencies to bear in many areas.

Autonomous Systems:

- transform and multiply existing forces with vast improvements in capacity, capability and efficiency;

- enable new concepts of operations and force structures so users can better meet mission objectives;

- make unmanned systems less dependent on continuous communication;

- automate the real-time tactical decision-making humans currently provide for manned and unmanned systems;

- improve the efficiency and accuracy of tactical decision-making required to operate multiple, cooperating systems in complex, dynamic, hostile environments;

- reduce overall manpower, and;

- provide an effective interface for humans to manage system behavior at all levels, from total force to individual subsystems.

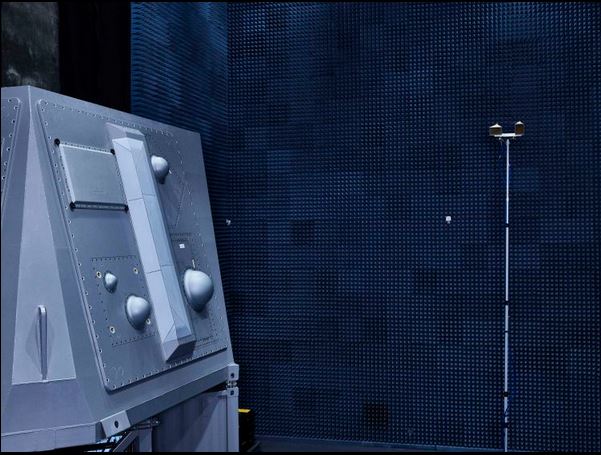

Advanced Manufacturing and Additive Manufacturing

Northrop Grumman’s innovative approach to advanced manufacturing seamlessly integrates digital technologies at the speed of relevancy. Our software makes our hardware better because we’re able to upgrade and accelerate new capabilities, which drives the efficiency, optimization and first-time quality our customers require.

Leveraging the digital environment in design enables rapid testing and adjustment of solutions before we physically manufacture items and place them on the air vehicle, greatly reducing risk. To speed up our design and build process, we are:

- Leveraging modeling and simulation, using high-fidelity, validated models to test and ultimately trust complex algorithms with thousands of varying inputs to ensure the desired effect.

- Generating digital models of new aircraft and flowing them into computational electromagnetic tools so we can see how new capabilities behave when installed on a platform.

- Leveraging vehicle design tools, with the use of reality goggles, which can assist in updating the design based on maintainability.

- Developing software, which can be used for vulnerability testing, giving us the ability to test before it’s compiled to ensure there’s a trusted code.

All of these advanced manufacturing approaches accelerate the design process, and we are working with our customers to leverage those same tools to accelerate the requirements for verification and validation to field programs more quickly than ever before.

Lean-Agile

Agile Transformation

At Northrop Grumman, we understand the importance of the mission and the need to deliver value at the speed of relevance. Lean-Agile and digital engineering are complementary solutions that promote a cohesive collaboration between development, security and operations working towards continuous and rapid integration and delivery. This is achieved through intimate and transparent collaboration across program teams and disciplines.

We understand the need for the entire organization to act with a Lean-Agile mindset, both internally and with customers and suppliers. We value partnership with our customers and suppliers in creating a quick feedback loop which is a proof point of our success in regular delivery of value. We inspect and adapt to the evolving needs of our business, suppliers, and customers.

Our Lean-Agile journey started over ten years ago with software-mission critical programs. We embrace our proven success with our Lean operations, which adheres to innovative thinking, built-in quality, and minimizing process waste with focus on value delivery and relentless improvement. Through our continued commitment to excellence and innovation, we have learned the value of applying Lean-Agile principles and practices to all aspects of our business and operations. As a result, our employees apply innovative thinking every day to our solutions and to our business and management practices leading to a more positive work experience. We have an exceptional community of Lean-Agile talent and thought leaders who coach, mentor, and model this growth mindset and are dedicated to a sustainable model for continuous improvement.

Together we create a Lean-Agile culture where digital transformation can thrive.

Increasing Collaboration with Space and Missile Systems Center by Implementing Agile Methodology

Northrop Grumman Delivers New Capabilities to Deployed Global Hawk Autonomous Aircraft

Ongoing improvements to Global Hawk underscore Northrop Grumman’s commitment to the United States Air Force’s ISR mission.

Northrop Grumman Increases Collaboration with Space and Missile Systems Center by Implementing Agile Methodology

Unified Platform Levels UP

Northrop Grumman is at the leading edge of a Lean-Agile and Development Security Operations (DevSecOps) revolution within the U.S. armed forces.

Northrop Grumman, Army Teams Preparing for Integrated Air and Missile Defense Weapon System Limited User Test

Read about Digital Transformation at Northrop Grumman

Digital Sustainment Tools Enhance Mission Readiness

Sustainment is a vital element of any product’s lifecycle.

Northrop Grumman to Develop Digital Twin of Company’s Testbed for Digital Mission Systems

Northrop Grumman Downselected as Sole Contractor for US Air Force F-16 Electronic Warfare Suite

Northrop Grumman Completes First Flight of Global Hawk Ground Station Modernization Program

How Northrop Grumman Is Giving Aircrews an Edge in Electronic Warfare

Going digital provides a generational leap in capability

Northrop Grumman Advances Maritime Electronic Warfare Capability with Follow On Production Contract From US Navy

Careers in Digital Transformation

Want to join us and support digital transformation? Northrop Grumman has been pushing the boundaries of technology for decades and continues to make advances across air, cyber, land, sea and space.

Explore these opportunities: start a career Defining Possible today.